Industries trust our hot dip galvanizing Plant in many sectors, including:

Hot Dip Galvanizing Plant Manufacturer

As one of the leading Hot Dip Galvanizing Plant Manufacturer in India, we put world-class solutions in place that provide long-lasting protection to steel and iron components. A hot dip galvanizing plant offers a steel with a layer of molten zinc that provides superior corrosion resistance, durability, and maintenance-free.We continue to combine with over forty years of experience in galvanizing, providing an end-to-end galvanizing project design, engineering, setup, and project execution, a turn-key project. Starting from concept to commissioning in its entirety, our solutions are customized to the unique needs of an industry anywhere in the world.

As an established hot dip galvanizing plant supplier and hot dip galvanizing equipment supplier, we provide all-glass energy-efficient, environmentally friendly, and cost-effective Plant that deliver the fastest payback and life value for our clients.

Features of Hot Dip Galvanizing Plant

- ✓ Modified Project Design - Personalized project solutions specific to the needs of the industry.

- ✓ Large Capacity Kettles - For uniform coating of zinc and maximum service life.

- ✓ Energy-Efficient Furnaces - Rapid pulse-fired high-speed systems for minimal fuel consumption.

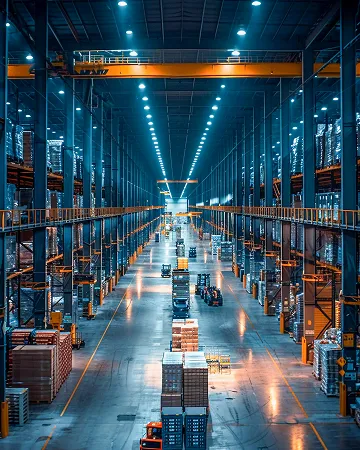

- ✓ Automated Material Handling - Smooth operation for loading and unloading for quicker production cycles.

- ✓ Environmental Compliance - Fume enclosure and scrubbing systems to help with pollution abatement.

- ✓ Rugged Construction - Constructed from a heavy-duty grade material to withstand extreme temperatures.

| Specifications of Hot Dip Galvanizing Plant: | |

|---|---|

|

Capacity

|

Pulse-fired / Gas-fired / Oil-fired |

|

Material

|

Quality steel and refractory products. |

|

Temperature Range

|

Up to 450°C – 470°C (best for melting zinc). |

|

Automation

|

Semi-automatic or fully automatic. |

|

Durability

|

Long-lasting kettles with protective linings to prolong the kettle's life cycle. |

|

Support Systems

|

Flux regeneration, drying ovens, fume enclosures, and scrubbers. |

Advantages of Hot Dip Galvanizing Plant

Corrosion protection

Provides excellent corrosion protection due to the thickness of the zinc coating as described above.

Durable

Provides a durable finish while needing little maintenance.

Cost Effective

A low-cost option with the fastest payback period.

Eco-Friendly

Meets international quality and environmental standards.

Longer service life

Increases the strength of the structure, allowing for a longer service life.

Environmentally responsible design

Reduced emissions and an environmentally friendly unit.

Flexibility

Provides flexibility with plant setup for small, medium, and large industries.

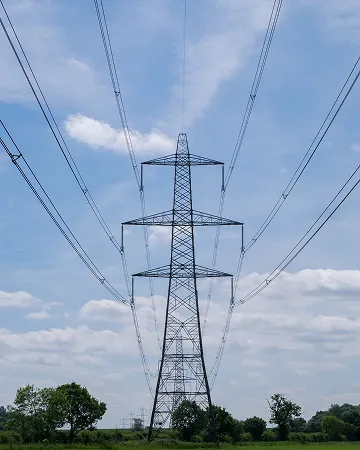

Industries We Serve

- Bridges

- Guardrails

- Poles

- Pipelines

- Solar structures

- Transmission towers

- Telecom towers

- Chassis

- Railway components

- Heavy vehicles

- Structural steel

- Industrial Machinery

- OEM parts

- Pipes

- Tanks

- Silos

- Farm-related equipment