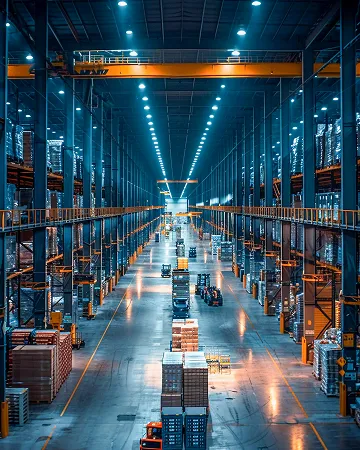

Industries trust our hot dip galvanizing Plant in many sectors, including:

Galvanizing Furnace Manufacture

A Galvanizing Furnace is a key constituent of a hot dip galvanizing plant to heat and hold molten zinc at the correct temperature for coating steel products. A galvanizing furnace achieves this by delivering uniform heat distribution in the galvanizing bath that guarantees a uniform zinc coating for greater corrosion resistance and reliable longevity of the steel structure.

Here, we design and manufacture galvanizing furnaces that are energy-efficient, long-lasting, and high-performance. All of our galvanizing furnaces meet international standards. We build our galvanizing furnaces with advanced combustion systems, strong refractory lining, and automation options to ensure the process is reliable and cost-effective. We can provide galvanizing furnace solutions from a small batch hot dip galvanizing setup to large industrial galvanizing furnaces for greater production. With sustainability in mind, design our galvanizing furnaces to reduce fuel consumption and emissions and ensure years of consistent performance.

Features of Galvanizing Furnace

- ✓ Pulse-fired high-velocity burners generate high-efficiency heat output.

- ✓ Consistent radiating heat with the capability of uniform melting of zinc.

- ✓ Heavy-duty refractory lining to offer robustness.

- ✓ Advanced temperature control and automation.

- ✓ Energy-efficient design management keeps your operational costs down.

- ✓ Low-maintenance design promotes a longer life span.

- ✓ Custom design is available to fit Plant of any size.

| Specifications of Galvanizing Furnace: | |

|---|---|

|

Furnace Style

|

Pulse-fired / Gas-fired / Oil-fired |

|

Use

|

Capacity for kettles of any size (can be manufactured to specification) |

|

Temperature Range

|

450°C - 470°C (can also be utilized to melt zinc) |

|

Construction

|

High-quality steel construction with refractory insulation |

|

Automation

|

Semi-automatic and fully-automatic versions |

Advantages of Galvanizing Furnace

Corrosion protection

Producing top-quality zinc coatings to stop rust on steel.

Cost-effective operation

Minimum fuel consumption means lower energy bills.

Cost Effective

Lower maintenance costs and longer product life

Long service life

Built with durability, so it lasts.

High productivity

Fast heat cycles create greater plant efficiency.

Environmentally responsible design

Reduced emissions and an environmentally friendly unit.

Custom-built designs

Furnaces designed for unique galvanizing plant designs

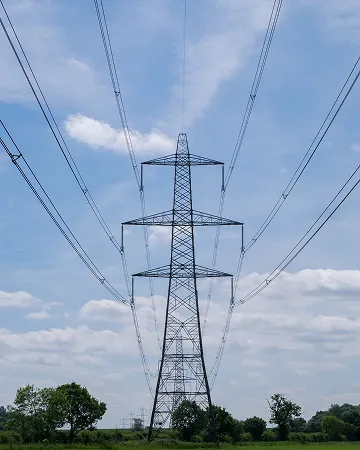

Industries We Serve

- Bridges

- Guardrails

- Steel poles

- Solar panel structures

- Telecom towers

- pipelines.

- Vehicle chassis

- Frames

- Steel parts

- Structural steel

- Machinery

- OEM parts

- Pipes

- Tanks

- Silos

- Farm-related equipment